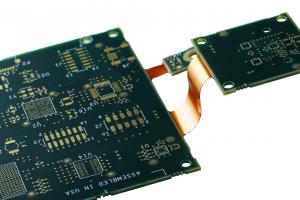

Rigid Flex PCBs

Pure PCB’s high quality Rigid-Flex printed circuit board capability is a cornerstone of our hybrid PCB capabilities. Our expertise provides our customers with reliable, high-quality solutions that eliminate the need for connectors and cables within any product.

Our quick turnaround rigid-flex circuit board solutions range from simple boards and board interconnects, through to the most complex of high-speed applications. With the ability to create multilayer PCBs (ranging from 1-22) and an available board thickness up to 20mm, our selection of base materials is standard and high TG FR4 & Polymide. Our rigid-flex PCB products have a minimum panel size of 600 x 450mm.

Types of Rigid-Flex PCBs available from Pure PCB

Here at Pure PCB, we have a range of surface finishes available for our flexible circuit boards. Any of the below finishes can be implemented for your design:

- ENIG

- Lead free HASL

- ENEPIG

- ASIG

- ISIG

- Immersion Tin

- Immersion Silver

The applicable quality standard of our rigid-flex PCBs is PC 6013 Class 3. We also have a selection of available stiffener materials including:

- Thermal adhesive

- Standard FR4

- Polymide

- Aluminium

Here at Pure, we are keen to help and support our customers in every way that we can – we’re proud to be associated with you and help you with your PCB needs. The early involvement of Pure PCB in a collaborative dialogue around your Rigid-Flex PCB design will only serve to benefit your production in the long run – those who contact us early in the process receive the most effective provision of optimised interconnect solutions.

How are Rigid-Flex PCBs made?

Rigid flex circuit boards use a combination of both rigid and flexible substrates laminated together to form a unified structure - this structure offers the benefits of a flexible printed circuit board while maintaining the features of a rigid board.

It is worth noting that rigid flex circuits are not the same as similar rigidised flex constructions which are flex circuits with electronic components supported by locally attached stiffeners. Rigidised flex construction is mechanical connection while rigid-flex PCBs are electrical connection.

Benefits of Rigid-Flex Circuit Boards

Rigid flex PCBs take on the features of a rigid PCB while retaining the benefits of a flexible PCB. These advantages include:

- Dynamism - investing in rigid flex PCBs leads to unlimited packaging geometry while retaining precision density and repeatability of printed circuits. Minimal geometry changes reduce the opportunity for impedance discontinuities – hence improving dynamism.

- Cost-effectiveness – investing in a rigid-flex circuit board can lead to a reduced material weight and need for parts.

- Reduced weight – rigid flex PCBs remove the need for connectors and cables between the individual rigid parts – this results in a reduced board size and a lighter system.

Pure Electronics Flex Rigid Capability Overview

| PCB Technology | Pure PCB Current Capability |

| Layer Count | 1 to 22 Layers |

| Available Board Thickness | Up to 20mm |

| Available Base Materials | Standard & High TG FR4 |

| Polymide | |

| Core Thickness | 25um Without Adhesive |

| Minimum Line Width and Space | 60um |

| Available Copper Thickness | Up to 35um |

| Minimum Solder Mask Dam | 65um |

| Maximum Panel Size | 600 x 450mm |

| Minimum Drill Size | 0.2mm |

| 10:1 Aspect Ration | |

| Available Surface Finishes | ENIG |

| Lead Free HASL | |

| ENEPIG | |

| ASIG/ISIG | |

| Immersion Tin | |

| Immersion Silver | |

| Available Stiffener Materials | Thermal Adhesive |

| Standard FR4 | |

| Polymide | |

| Aluminium | |

| Applicable Quality Standard | IPC 6013 Class 3 |