Flexible PCBs

At Pure PCB, our flexible capability is a cornerstone of our PCB capabilities. We provide our customers with reliable, high-quality solutions that eliminate the need for connectors and cables within any product. Get in touch with a member of our friendly sales team today for more information on our flex capabilities.

What is a Flexible PCB?

Also referred to as flex circuits, flexible PCBs are able to twist and fold to fit the shape of your board designs – - a flexible PCB allows for the circuitry to be designed to fit the electronic device or product, as opposed to building the device to conform to a rigid circuit board.

The board’s bending capability can be altered to fit your requirements and needs – we also offer multilayer PCBs and rigid flex solutions for customers looking for a more rigid structure.

Types of flexible PCBs available

Here at Pure PCB, we have a range of surface finishes available for your flexible circuit boards:

- ENIG

- Lead free HASL

- ASIG

- ISIG

- Immersion Tin

- Immersion Silver

The applicable quality standard of our flexi PCBs is also PC 6013 Class 3. We also have a selection of available stiffener materials including:

- Thermal adhesive

- Standard FR4

- Polymide

- Aluminium

Advantages of flexible PCBs

Flexible circuit boards offer many advantages due to their bend and flex properties:

- Wiring Solutions – investing in flexible PCBs allows you to fit your circuit board to your product by allowing you to twist the circuit board into areas that a single sided, rigid circuit cannot. The lack of rigidity of our PCBs offers improved wiring solutions.

- Lighter products – a product with a flex circuit board is likely to be lighter as the material used for flex circuit boards is not as heavy as the materials used for a rigid counterpart.

- High Temperature – most of our flex circuit boards are built with polyimide, a material that dissipates heat better than most. Therefore, flexible boards can be added to hotter areas that would cause damage to rigid boards.

- Durability – alongside the high temperature resistance, flex circuits are designed to withstand chemical corrosion and radiation & UV exposure. Products with a flexible printed circuit board tend to be highly durable.

- Miniaturisation – flexible boards contain a lower number of device interconnects meaning miniaturisation is a much more viable option for a product design during the PCB fabrication.

RF PCB overview:

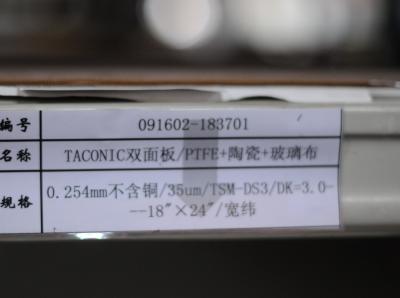

| PCB | Pure PCB Current Capability |

| Layer Count | 2-24 Layers |

| RF Materials Availabe | PTFE |

| FR4 | |

| Polymide | |

| Polyester | |

| Ceramic | |

| Laminates Brands Utilised | Taconic |

| Rogers/Arlon | |

| Nelco | |

| Sheldahl | |

| Isola | |

| Thermal Capability | From 0.82 W/mK |

| Available Copper Weight | 0.5 Oz to 15 Oz with 8 Oz UL Certification |

| Minimum Line Width & Space | From 0.075 mm |

| RF Complian Surface Finishes | Electroless Nickel Immersion Gold |

| ASIG | |

| ISIG | |

| Lead Free Hot Air Solder Level | |

| Dielectric Thickness | 0.1 to 3.5mm |

Why choose Pure Electronics

At Pure Electronics we pride ourselves on supplying competitively priced flexible PCBs of the highest quality to a global market. Our helpful customer service team and extensive knowledge made us the global PCB supplier we are today. We provide flexible PCBs to a wide spectrum of customers in a variety of sectors.

For more information on our flexible printed circuit boards, get in touch with a member of our expert team. Submit your PCB Gerber Files here and one of our expert team will give you a call.